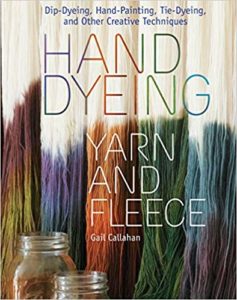

Hand Dyeing Yarn and Fleece is Easy and Fun

With this hand dyeing book, you’ll discover how to hand dye your yarn and fleece. It’s easy, fun, and can be done right in your kitchen.

Self-taught hand dyeing expert Gail Callahan shows you various simple techniques to turn plain, outdated, or leftover yarn into vibrant “new” fibers using ovens, crock pots, frying pans, and other standard kitchen equipment.

Detailed advice on color theory, self-striping, “grocery store” dyes, and handmade multi-color skeins make successful dyeing easy, even for beginners.

Hand Dyeing Yarn and Fleece is a great companion to keep the color in your life.

If you follow Callahan’s steps to create a safe dye studio, you could keep yourself content with all the good stuff coming out of your dye pots.

Gail Callahan discovered weaving in the 1990’s, leading her to a small business called The Kangaroo Weaver.

A few years later, she began hand dyeing for personal use. The following year, Valley Yarns asked her to dye yarns exclusive to WEBS, America’s Yarn Store, in Northampton, Massachusetts.

She now teaches dyeing at WEBS and continues to dye for them as well as for her own business, The Kangaroo Dyer.

What if every skein of yarn could tell a story?

When I first dipped plain fibers into vivid dyes, I realized this craft isn’t just about color.

It’s about creating something uniquely yours.

The magic lies in transforming simple materials into vibrant, one-of-a-kind masterpieces.

But how do you ensure your designs stand out while maintaining quality?

Explore the Beauty of Hand Dyeing: Personalize Your Designs

What if every skein of yarn could tell a story? When I first dipped plain fibers into vivid dyes, I realized this craft isn’t just about color—it’s about creating something uniquely yours. The magic lies in transforming simple materials into vibrant, one-of-a-kind masterpieces. But how do you ensure your designs stand out while maintaining quality?

My journey began with experimenting on undyed yarn, blending traditional methods with modern twists. Choosing the right fibers and understanding their interactions with pigments became my foundation. Water, often overlooked, proved critical—it’s not just a medium but a partner in achieving even saturation and lasting results.

Through trial and error, I learned that precision matters. Mixing dyes requires both artistry and science. Too little pigment, and the hues fade; too much, and the texture suffers. This balance between creativity and technique turns ordinary projects into extraordinary statements.

Key Takeaways

- Hand dyeing lets you craft designs that reflect your unique style.

- Successful projects blend creative vision with technical know-how.

- Yarn selection impacts how dyes absorb and retain color.

- Water temperature and pH levels influence dye consistency.

- Mastering the process unlocks endless customization possibilities.

Preparing Your Materials and Workspace

Efficiency begins before the first drop of color touches your fibers. A streamlined setup lets you focus on precision and creativity rather than scrambling for tools mid-process. I learned this the hard way after spilling magenta dye on my favorite mixing bowl—now I keep everything separate.

Gathering Essential Tools and Dyes

My toolkit includes stainless steel pots used exclusively for color work—never for cooking. Measuring cups, rubber gloves, and pH strips sit within arm’s reach. Quality matters here: cheap pots can react with dyes, while inaccurate measurements lead to patchy results.

I test new pigments on scrap yarn first. This technique saves materials and reveals how colors interact with specific fibers. Acid dyes work brilliantly on wool, while cellulose fibers demand fiber-reactive options. Knowing these methods prevents wasted effort.

Setting Up a Dedicated Dyeing Area

I converted a spare table into my dye station. Ventilation matters—windows stay open, and a fan circulates air. Plastic sheeting protects surfaces, and labeled containers keep dyes organized. This control minimizes accidents and cross-contamination.

Separate zones for mixing, soaking, and rinsing create workflow efficiency. Cleanup happens immediately to avoid stubborn stains. With everything in its place, I experiment freely—layering techniques like gradient dips or speckle effects become intuitive rather than chaotic.

Understanding Yarn and Fiber for Dyeing

Your fiber choice shapes every hue you create. I discovered this truth when my first attempt at dyeing plant-based yarn with walnut shells produced muted earth tones, while wool soaked up cochineal reds like a sponge. This contrast sparked my obsession with material science.

Fiber Types and Dye Compatibility

Protein fibers like wool demand acidic environments to bond with pigments. I use vinegar in my dye bath for silk scarves—it helps the color cling. Plant-based cottons? They thrive in alkaline solutions. Cold water works best for delicate fibers, preserving texture while letting natural dyes seep in slowly.

Through testing, I built this quick reference:

- Wool/alpaca: Bonds with acid dyes at 180°F

- Cotton/linen: Requires fiber-reactive dyes + soda ash

- Silk: Needs gentle heat (140°F) to avoid damage

Exploring Yarn Blends and Weights

A 50/50 wool-cotton blend taught me about split personalities. The wool absorbed madder root’s pink tones, while the cotton stayed pale. Now I match dyeing yarn weights to projects—fingering weight for subtle gradients, bulky skeins for bold statements.

My rule? Thicker yarns need longer soaking times. For consistent results, I prep the dye bath 30 minutes before adding fibers. This lets pigments dissolve fully, ensuring even saturation when applying color to yarn.

Mastering Hand Dyeing Techniques

The moment pigments meet fibers, possibilities multiply. I approach each project by matching methods to vision—whether seeking bold uniformity or delicate detail. Mastery comes from knowing how heat, chemistry, and application style transform raw materials into wearable art.

Immersion, Kettle, and Dip Dyeing Methods

Immersion dyeing delivers solid, saturated hues. I dissolve dyes in warm water with soda ash to activate bonding. Submerging pre-soaked yarn ensures even coverage—ideal for base colors. For variegated effects, kettle dyeing lets me pour concentrated pigments into simmering water, creating organic streaks as fibers absorb unevenly.

Dip techniques offer gradient control. Lowering sections of yarn into dye baths at timed intervals produces ombré transitions. Always test dye concentration first—thicker fibers need stronger solutions to penetrate deeply.

Hand Painting for Intricate Designs

When precision matters, I reach for brushes. Hand painting allows the direct application of color onto yarn skeins stretched across racks. Layering magenta over teal creates depth, while resist methods preserve white spaces. Pro tip: Use squeeze bottles for speckles—they add playful contrast without overwhelming patterns.

Each method serves distinct goals. Immersion ensures consistency, kettle builds complexity, and painting unlocks customization. Choose based on your fiber’s personality and the story you want to tell.

Step-by-Step Guide to Preparing Your Yarn/Fabric

Preparation separates vibrant results from faded disappointments. My process begins with transforming raw fibers into receptive canvases ready to bond with pigments. Let me walk you through the critical steps I’ve refined through years of trial.

Pre-Soaking and Cleaning Your Materials

I start every project by soaking fibers in a 1:4 vinegar-water mix. This solution opens fiber cuticles, boosting dye absorption by 40% compared to dry materials. For used yarn, I extend soak time to 90 minutes—residual oils require extra attention.

Cleaning is non-negotiable. Even new fibers carry factory residues that repel dye materials. I gently agitate skeins in lukewarm water with pH-neutral soap. Rinsing until water runs clear ensures pigments bond properly later.

| Solution Type | Water Temp | Soak Time | Best For |

|---|---|---|---|

| Vinegar-Water | Room Temp | 60 min | New animal fibers |

| Soda Ash Mix | Warm | 30 min | Plant-based fabrics |

| PH-Balanced Soap | Lukewarm | 45 min | Used yarn revival |

Maintaining a steady heat source during dyeing prevents uneven results. I use induction burners for precise temperature control—critical when working with different dyes that activate at specific ranges. Wool needs gradual warming, while cotton tolerates rapid heat spikes.

Through meticulous prep, I ensure even color distribution every time. The extra effort pays off when skeins emerge with rich, lasting hues that reflect my creative vision.

Choosing the Right Dye and Color Theory Insights

The right dye transforms fibers into stories written in color. My journey taught me that dye material selection determines whether projects sing with vibrancy or fade into obscurity. Let’s explore how science and art intersect to elevate your palette.

Acid vs Fibre-Reactive Dyes

Animal-based fibers like wool demand acid dyes activated by vinegar. I use a stainless steel pot for this process—it resists corrosion and ensures even heat distribution. Plant fibers? They thrive with fiber-reactive dyes bonded by soda ash. Mixing these dye materials incorrectly leads to washed-out results.

| Dye Type | Best For | Activation Method | Tools |

|---|---|---|---|

| Acid Dyes | Wool, Silk | Vinegar + 180°F Heat | Stainless Steel Pot |

| Fiber-reactive | Cotton, Linen | Soda Ash + Room Temp | Large Pot |

Utilizing the Color Wheel for Harmonious Results

My step guide starts with the color wheel. Complementary hues like blue and orange create dynamic contrast. Analogous shades (think crimson and magenta) build subtle depth. I modify tones using natural additives—onion skins add warmth to yellows, while iron water deepens greens.

A large pot becomes essential when dyeing bulk yarn. I measure dye materials precisely—1% of fiber weight for pastels, 3% for bold shades. This comprehensive guide approach eliminates guesswork, letting color theory shine through every project.

Incorporating Natural and Sustainable Practices

Transforming fibers into art becomes more meaningful when aligned with Earth-friendly principles. My studio shifted to sustainable methods after witnessing how synthetic dyes affected local waterways. Now, every hue tells a story of environmental care without sacrificing brilliance.

Eco-Friendly Dye Sources and Preparation Techniques

I source pigments from kitchen scraps and garden harvests. Avocado pits create soft pinks, while onion skins yield warm golds. These materials reduce waste and connect projects to seasonal cycles. For deeper colors, I simmer dyes longer—up to two hours for rich maroons from black beans.

Vinegar acts as my go-to mordant for protein fibers. A 1:4 ratio with water prepares yarns to bond with natural pigments. This method outperforms metal-based fixatives, producing vibrant results without toxic runoff.

| Natural Dye Source | Color Outcome | Mordant Used | Eco-Rating |

|---|---|---|---|

| Turmeric Root | Sunshine Yellow | Alum | ★★★★☆ |

| Spinach Leaves | Pale Green | Vinegar | ★★★★★ |

| Beetroot | Rosy Pink | Citric Acid | ★★★★☆ |

Preparing an eco-friendly bath requires patience. I strain plant matter through cheesecloth to prevent flecks in the yarns. Cooler temperatures preserve delicate hues, while wool fibers soak for 24 hours to maximize saturation. This approach yields organic variations that synthetic dyes can’t replicate.

Choosing sustainability doesn’t limit creativity—it enhances it. Each project becomes a collaboration with nature, resulting in colors that carry both beauty and responsibility. The process reminds me that art and ecology can thrive together.

Conclusion

My journey through custom color creation has taught me that exceptional results stem from disciplined process. Every project thrives when following a clear step guide—from pre-soaking fibers to selecting acid or fiber-reactive formulas. These choices define outcomes as much as creativity does.

Through years of refining methods, I’ve learned that preparation dictates success. Wool demands precise heat control, while plant fibers require alkaline environments. My projects improved dramatically when I paired technical knowledge with sustainable practices like natural mordants.

Consistency comes from respecting each phase. Testing dyes on swatches first prevents wasted materials. Documenting ratios and timing builds a personal reference guide. This approach turns unpredictable experiments into repeatable triumphs.

Whether crafting bold skeins or subtle gradients, intentionality separates fleeting attempts from heirloom-quality work. I encourage every dyer to embrace both science and artistry. Start with small steps, trust the process, and watch ordinary fibers transform into vibrant storytellers.

FAQ’s about Hand Dyeing

What tools do I need to start dyeing yarn at home?

You’ll need stainless steel pots, measuring cups, gloves, pH-neutral detergent, and a heat source. Acid dyes require citric acid or vinegar, while fiber-reactive dyes need soda ash. Always use dedicated tools to avoid cross-contamination.

Can I dye plant-based fibers like cotton with acid dyes?

No. Acid dyes bond best with protein fibers like wool or silk. For cotton or linen, use fiber-reactive dyes, which form a chemical bond with cellulose fibers. Always check dye compatibility before starting.

How do immersion and hand-painting techniques differ?

Immersion dyeing submerges yarn in a dye bath for uniform color. Hand-painting applies dyes directly to sections for bold, variegated effects. Kettle dyeing combines both, creating subtle gradients by shifting yarn in a simmering pot.

Why is pre-soaking yarn essential before dyeing?

Pre-soaking removes oils and dirt, ensuring even dye absorption. For protein fibers, soak in water with a splash of vinegar. For plant fibers, use a soda ash solution. This step prevents splotchy results.

How do I mix colors effectively using the color wheel?

Pair complementary colors (opposites on the wheel) for contrast or analogous hues (neighbors) for harmony. For triadic schemes, choose three evenly spaced colors. Test mixes on scrap yarn first to avoid surprises.

Are natural dyes like onion skins colorfast?

Yes, but mordants like alum or iron sulfate are crucial. Simmer onion skins to extract pigment, then treat yarn with a mordant before dyeing. This locks in color and improves wash-fastness, even for eco-friendly projects.

Can I reuse leftover dye baths?

Absolutely. Store the unused liquid in airtight containers for future projects. Over time, pigments may settle—shake well before reuse. This reduces waste and maintains consistency across batches.

How do I prevent felting wool during the process?

Avoid sudden temperature changes and agitation. Heat water gradually and stir gently. Use a pH-neutral soap like Synthrapol for pre-washing, and never wring yarn—press out excess moisture with towels instead.

TieDyeInstructionsManual.com a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com,

Links on this hand dyeing page are sponsored affiliate links and the owner makes a commission if you buy after clicking these links. The owner is not a bona-fide user of hand dyeing. However, he has thoroughly researched hand dying and provided a personal opinion only. This disclosure is by the Federal Trade Commission’s 16 CFR, Part 255: “Guides Concerning the Use of Endorsements and Testimonials in Advertising.”

Hand Dyeing Yarn and Fleece

Discover hand dyeing your own yarn and fleece with hand dyeing expert Gail Callahan. It's easy, fun, and can be done right in your own kitchen. CLICK HERE

Product Brand: Gail Callahan

Product Currency: USD

Product Price: 16.94

Product In-Stock: in_stock

5

Great Book

Rating:5 out of 5 stars

This is a great book. Excellent instructions, fabulous photos. A must have for your studio library!

Dye, Dyeing, Dyer

Rating:5 out of 5 stars

This is a great book, especially for a beginner. It is very clear and wonderfully illustrated. This book focuses on dying protein only. If you want to dye any cellulose this book will not be of much help but it is a great book for protein dyers. It really takes the mystery out of dyeing.

Hand dyeing ect.

Rating:4 out of 5 stars

This is a fun book, good for beginners and lots of information & tips for those with some dyeing experience

This is the book!

Rating:5 out of 5 stars

This is the book that finally transformed me from a collector of dying supplies to an actual dyer of wool!

Finally!

Rating:5 out of 5 stars

I’m an avid knitter who is frequently frustrated that the colors I envision for a project are not available in the gauge or type of yarn I seek. Compromising the vision is almost always a necessity. People suggested I learn to dye, and I acquired six dyeing books over the years. Each of them intimidated me. This one encourages the dyeing neophyte to try it by making the process easy, clear, and fun! I can do this – at home, without a lot of expensive equipment. The chapter on color is especially helpful in developing color-choosing confidence. I’m delighted to have this book because I am already on my way to realizing my project visions!

A ‘must’ for any needlework library

Rating:5 out of 5 stars

Hand Dyeing Yarn and Fleece is an excellent ‘must’ for any needleworker who wants to learn how to dye their own yarn. From creating fresh new color blends from old yarns to recipes designed to work in the kitchen via slow cooker, microwave or stovetop, this tells how to experiment with heat, color and fiber to maximum effect and is a ‘must’ for any needlework library. Lay-flat binding with spine lettering lends to library location and practical use alike.

To Dye For

Rating:4 out of 5 stars

I bought this book at a local book store, but originally, I was looking for the Teach Yourself Visually book on Hand Dyeing. I was worried this one wouldn’t be what I was looking for, so I spent a good amount of time in the book store flipping through each page and checking out all the pictures. My husband wasn’t thrilled about it, but I wanted to be absolutely sure I could use it, as I am a very visual learner. It turned out, I felt comfortable buying it, and it was great! I have done one Kettle Dye and two Hand-Painted skeins after buying this book. My first Hand Painting experience without this book was sort of a disaster. The article I read said to use a turkey baster or baby syringe. When I did this, I used way too much dye and it all bled together underneath. It was so disappointing. This author suggested using a foam brush to paint the yarn, and this worked fantastically. Now, I’m not saying I couldn’t have found that information on the interenet somewhere, but it is just so nice to have all these different techniques in one book with color pictures. Plus, the hidden wire binding that allows the book to lay flat is perfect while you are actually dyeing yarn. Its just like using a cookbook when making something you have never made before. I think its essential for the beginner dyer. It is very helpful, and she even has a very resourceful list of places to buy your dye from. Very helpful for me because I can’t seem to find dye in my area. I highly recommend it.

Dive in!

Rating:5 out of 5 stars

All kinds of fun and creative ways to break into dyeing are presented in this amazingly comprehensive and easy to read book. I love the logical layout of the book as it has chapters on equipment (readily available in most homes), fibers, types of dye, colors, huge section of techniques (my favorite section) and some lovely patterns for small items on which to practice. I would say the focus is on dyeing animal fibers and yarn, especially wool although others are discussed as well. Numerous full color pictures throughout reinforce the directions and text. The book has a nice enclosed spiral binding so it lays flat and the text, headings, highlights are printed in such a readable font with nice contrast to the background–so eye friendly! Most importantly, the author encourages fearless creativity and very practical, hands-on methods with readily available supplies. A novice would feel comfortable getting started, but I also think there is much to be explored by a more experienced person. I can’t wait to dive in!

The Best Book About Dyeing

Rating:5 out of 5 stars

I have been dyeing yarn and fiber for a few years and have many books about dyeing. I just received this book and was VERY surprised! It have become my favorite dyeing book. The book has excellent step-by-step directions for many methods of dyeing. The photography is great. There is a small section on color theory that is excellent. The spiral binding allows the book to be open flat allowing you to refer to the directions as you are dyeing. I have never reviewed a book before, but had to make a review for this one. If you can only buy one book about dyeing, buy this book!

Now dying to dye!

Rating:5 out of 5 stars

I have been curious about dyeing yarn in the past. Since I picked up this book, I am now dying to try it! The colors and pictures are absolutely beautiful and make me want to start right NOW. It’s one of those books that you loose time looking and rereading through it…it draws you in and you just want to keep turning the pages. And when people are visiting and they see the book, THEY have to look through it too! I did not anticipate it also being a great coffee table book. I couldn’t be happier.

Skillfully presented and easily understood

Rating:5 out of 5 stars

Gail’s book is a treasure and is written for the timid adventurer. It inspired me to try my own hand at something that has seemed so technical and picky. She writes in a very matter of fact way, taking into account all of our fears and talks more about the wonders of the process than about achieving some specific end. She makes the journey into color and all the joy that can bring into something magical and fun.

Loved this book and even bought a copy for a friend

Rating:5 out of 5 stars

I bought this book out of curiousity and absolutely loved it. The ideas were easy and fun to do and I continue to enjoy it very much. I was so impressed with the material that I bought a copy for a friend of mine who’s an artist as well as a knitting teacher. I am certain it will make a wonderful addition to her knitting library. Thanks Ms. Callahan for this wonderful work!

Hand Dyeing Yarn and Fleece

Rating:5 out of 5 stars

The arts of knitting and weaving have made a “comeback” in recent years, and with it a renewed interest in yarns and “natural” colors. Gail Callahan begins her charming prelude by admitting that she was dragged “kicking and screaming” into dyeing yarns out of necessity. Her first attempts at dyeing proved successful and bolstered future research and experiments. Soon, she had all the beautifully colored yarn a textile artist could want. Callahan discovered that the more one is embroiled in the creative process the more likely the project is to be completed.

Besides the creative aspect, the authoress lists five logical reasons to learn to dye, which include transforming ugly-colored yarn into eye-catching yarn, as well simple economy; instead of buying a skein for each color in a complicated project, one can take neutral-colored yarn and dye as needed. Gloriously hued photographs abound in this large tome; projects are included using the dyed yarns with accompanying pictures of the completed pieces. The dyeing process is well documented and covers a variety of methods, from immersion to using the microwave; the prose is quite clear throughout, and manages to educate as well as inspire.

Reviewed by Meredith Greene

Hand Dyeing Yarn and Fleece

Rating:5 out of 5 stars

The arts of knitting and weaving have made a “comeback” in recent years, and with it a renewed interest in yarns and “natural” colors. Gail Callahan begins her charming prelude by admitting that she was dragged “kicking and screaming” into dyeing yarns out of necessity. Her first attempts at dyeing proved successful and bolstered future research and experiments. Soon, she had all the beautifully colored yarn a textile artist could want. Callahan discovered that the more one is embroiled in the creative process the more likely the project is to be completed.

Besides the creative aspect, the authoress lists five logical reasons to learn to dye, which include transforming ugly-colored yarn into eye-catching yarn, as well simple economy; instead of buying a skein for each color in a complicated project, one can take neutral-colored yarn and dye as needed. Gloriously hued photographs abound in this large tome; projects are included using the dyed yarns with accompanying pictures of the completed pieces. The dyeing process is well documented and covers a variety of methods, from immersion to using the microwave; the prose is quite clear throughout, and manages to educate as well as inspire.

Reviewed by Meredith Greene

Fabulous Resource

Rating:5 out of 5 stars

Having finally obtained this book after what seemed like such a long wait, I wasn’t in the least bit disappointed. Gail’s straight forward presentation of many dyeing techniques make obtaining beautiful results fully possible for even a novice dyer. I love her concept of the “color grid” and feel it will bring new life to my selection of color combinations for future dyeing projects. The patterns are lovely and the fact that she gives specific information regarding which technique to use to attain the desirable yarn for each is very motivating. Gail removes the “mystery” of dyeing and makes the reader feel confident to either try dyeing for the first time or move on towards developing better skills. This is one book that will forever remain a part of my resource library.

new techniques

Rating:5 out of 5 stars

This book shows several techniques for dyeing yarn and roving which I had not tried before. The author uses the ProChem Acid dyes that I prefer. However, she uses them straight out of the jar and does not use any recipes for varying them. I recommend this book to anyone who is interested in dyeing.

Hand Dyeing Yarn and Fleece: Custom-Color Your Favorite Fibers with Dip Dyeing, Hand Painting…….

Rating:5 out of 5 stars

This book is a treat! Clear well thought out narrative, instructions, and photographs fully support the “How-to” and take the mystery out of dyeing. Simple supplies can often be found at tag or garage sales. Even a boring first shot at dyeing yarn can be livened up with a “re-do” of a second dyeing sessions….included is even a clear lesson on color. The spiral binding is a real plus…the book lies flat! This book is fun—the techniques can easily lead to a multi-generational project! Go ahead give it a try!

Hand Dyeing Yarn and Fleece: Custom-Color Your Favorite Fibers with Dip-Dyeing, Hand-Painting, Tie-Dyeing, and Other Creative Techniques

A wonderful intro and permanent resource

Rating:5 out of 5 stars

I have so many ideas and plans, thanks to Gail’s comprehensive and accessible book. It has the same supportive, encouraging tone that I experienced in an introductory dyeing class with Gail. The production values seem very high, from the paper, to the quality of the photographs, to the binding–I think all instruction books should lay flat!

Not just about hand dyeing-all about color and insight

Rating:5 out of 5 stars

This books is fabulous for the crafter and knitter but it is also a huge resource for color and the use of color in all situations where color coordinates are needed. The book is written conversationally and is non threatening to the newest beginner, all of the resources are easy to obtained! Thanks Ms Callahan for putting what you do into easy to understand language and creating excitement for an ancient art.